We are your one-stop shop for all your powder coating needs: custom batch, production and sandblasting. Our pride is the highest quality of powder coating services we can provide for the greater toronto area. Our aim is to be your first and only choice when it comes to ensuring your product get the look and durability you seek.

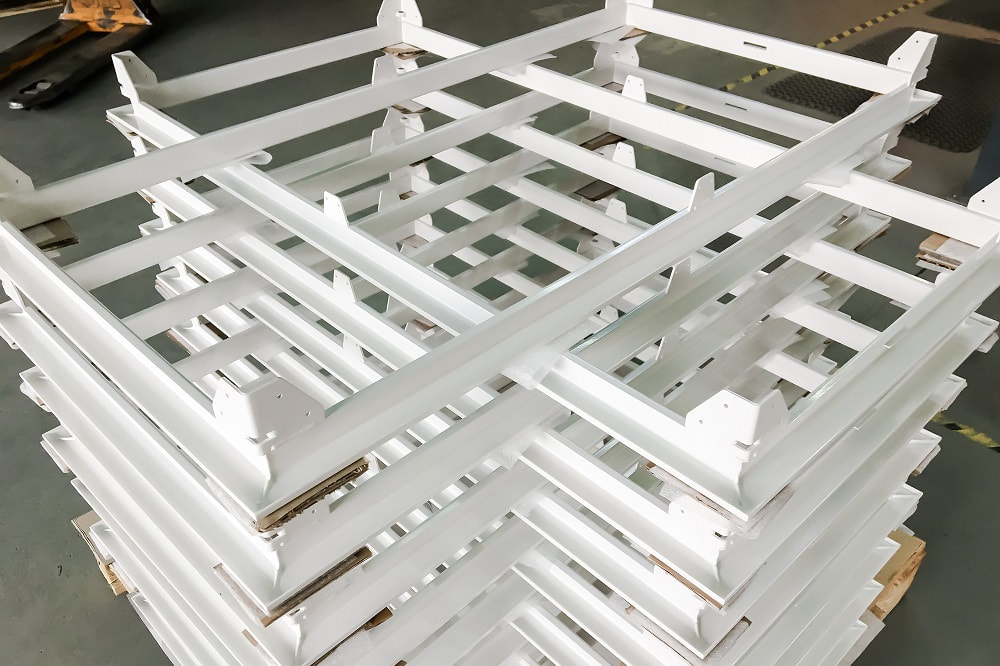

Our facility is designed to serve and accommodate all your powder coating, sandblasting, and stripping needs, whether they are large or small.

The process uses powder resin bases, such as epoxy / polyester / polyurethane & acrylics, along with coloured pigments blended into a fine powder consistency.

The powders are then sprayed on metal products through a specially designed electrostatic powder coating spray gun via clean dry compressed air. Because of the electrostatic charge received from the powder coating gun, the powders are attracted to the metal products in a uniform consistency. The products are then transferred through a high temperature powder coating bake oven which transforms the powder to a liquid, then to a gel and finally to a cured state, forming a molecular fusion bond to the substrate.

Powder coating provides better coverage compared to liquid paints. For some complexly designed wheel rims, certain facets of the rim can be difficult to reach with liquid paints. With powder coating, however, due to the electrostatic method combined with the curing process, even the most difficult-to-reach parts of the rim get adequate coverage.

The results is a surface-to-coating bonding unlike any other a finish, both enhancing the beauty and increasing the durability of your products.

Getting your rims redone is something nice that you can do for yourself, but why not do something nice for the environment while you’re at it? Opting to use powder coating over liquid paints is better for the environment. Liquid paints contain volatile organic compounds that are harmful to the ozone, as well as to anyone who breathes them in. Plus, excess liquid paint is nearly impossible to capture and reuse. Powder coating, on the other hand, contains no dangerous VOCs and any excess powder can easily be recycled.